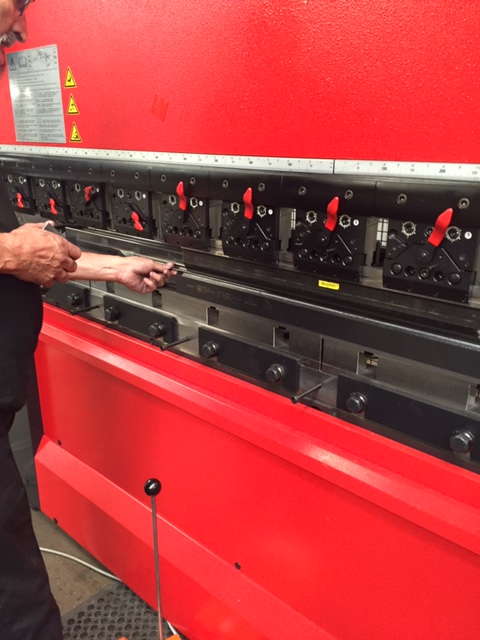

Aldermans has invested in a brand new press brake, with high-tech features to provide exceptional accuracy and efficiency.

The new Amada HFE1003 3i was commissioned in July 2015 as a replacement and upgrade for an older press brake.

Clever features on the new machine will mean that work can be progressed more quickly, with typically a 60% time saving on some complex folded pieces.

Aldermans has invested in a brand new press brake, with high-tech features to provide exceptional accuracy and efficiency.

The new Amada HFE1003 3i was commissioned in July 2015 as a replacement and upgrade for an older press brake.

Clever features on the new machine will mean that work can be progressed more quickly, with typically a 60% time saving on some complex folded pieces. The ‘one-stroke tooling’ feature allows different material thicknesses to be accommodated in one layout, saving on tool set-up time. A user-friendly tool library helps operators to quickly set up complicated parts; and a bar code reader allows for accurate repeatability of programmes.

The 18.5” multi-touch LCD panel has intuitive smartphone-style operation. This shows all the programme call, bend sequence, set up and processing information on one screen – so operators can have clear, visual control over the entire process. This screen also offers multiple views, such as angle, depth, 2D or 3D.

Extra features include precise bend measurement, transmitted wirelessly, coupled with angle auto-correction. The ‘Eco Drive’ system offers economy features, such as reduced energy usage, lower noise levels and reduced maintenance needs.

Despite all the automated features, there is still a hand wheel to adjust all axes manually if required.

“We’re very pleased to continue our programme of ongoing machinery investment,” commented Managing Director Karen Friendship. “Ensuring we keep the latest technology on the shopfloor means our customers can benefit from swifter and more accurate production. Our staff can also benefit from being trained on the new machine, which enhances their skills.”

Grant funding towards the new press brake was sourced from the North Devon ‘Unlocking Business Investment’ scheme, supported by the Regional Growth Fund.

Below: the new press brake in action in the Aldermans factory.