Advanced CNC Machining for Reliable & Accurate Results

CNC turning services for precision metal

Exceptional Accuracy & Quality

High-precision

CNC turning services

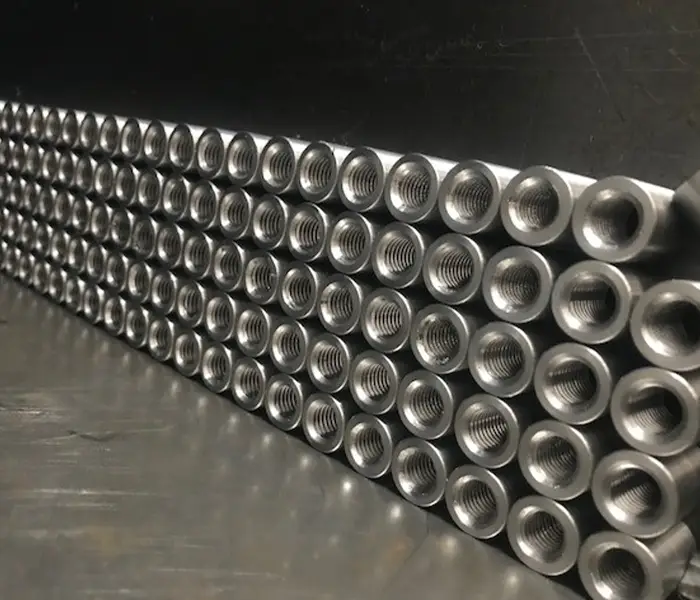

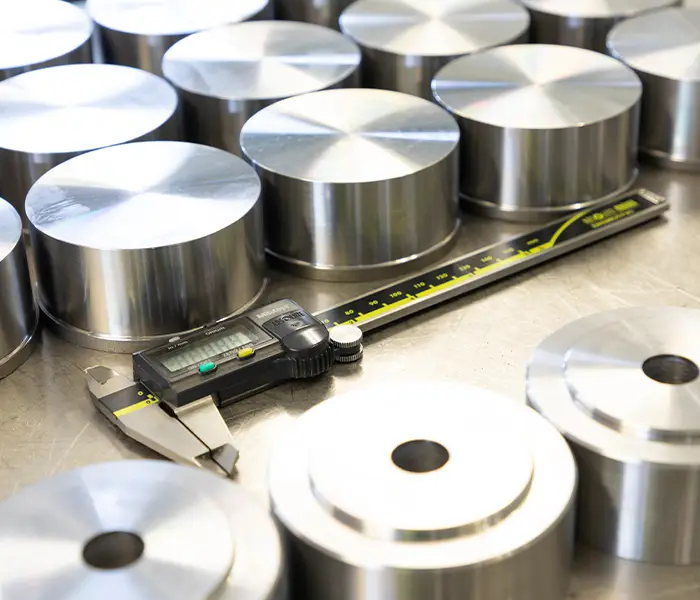

Our CNC turning services deliver high-precision metal components tailored to the exact specifications of each project. Using state-of-the-art CNC lathes from XYZ and Mazak, we manufacture components with exceptional accuracy. Our efficient processes ensure consistent quality, complimented by high-volume production.

Precision Equipment & Rigorous Standards for Reliable Results

Advanced CNC turning

capabilities with quality assurance

Our CNC turning services utilise state-of-the-art equipment and rigorous quality control measures to ensure precision, efficiency, and consistency across every project. By integrating advanced CNC lathes with thorough inspection processes, we deliver exceptional quality and reliability for both prototypes and large-scale manufacturing.

Automatic bar-fed

lathes

Supporting solid and tubular bars up to 50mm in diameter, with manual setups for larger dimensions. These machines enable high-volume production with consistent results.

Multi-axis

movement

Sub-spindle and Y-axis capabilities allow for complex geometries to be created in a single setup, reducing lead times and improving precision.

Precision

tolerances

Achieving tolerances as tight as ±0.001mm, our equipment ensures components meet exact specifications.

Single set-up

manufacturing

With the use of a sub-spindle, we can manufacture complex items in a single setup, eliminating the need for double handling.

Continuous

operation

Lights-out machining allows for round-the-clock production, ensuring timely delivery for high-volume orders.

Precision Techniques for Customised Metal Parts

Comprehensive

CNC turning services

Our CNC turning capabilities support a wide range of machining operations, offering versatility across various applications and enabling the production of everything from simple parts to intricate multi-feature components with reliability and consistency in every project.

Turning

Our CNC turning capabilities support a wide range of machining operations, ensuring versatility across various applications:

Boring

Enlarging holes with high accuracy to match design specifications.

Reaming

Refining hole sizes for seamless fits and improved functionality.

Thread-cutting

Crafting both internal and external threads to exacting standards, suitable for mechanical assemblies.

Chamfering

Smoothing edges for enhanced safety and easier assembly of components.

Versatility Across a Range of Metals

Materials & application

in CNC turning

Our CNC turning processes are compatible with a wide variety of materials, ensuring flexibility for different applications:

Mild steel:

Our CNC turning processes are compatible with a wide variety of materials, ensuring flexibility for different applications:

Stainless steel:

Corrosion-resistant and durable, ideal for medical, food-grade, and architectural projects.

Brass & aluminium:

Lightweight and robust, commonly used in aerospace, automotive, and electrical applications.

Engineering plastics:

Excellent for components requiring non-metallic properties such as low friction or high wear resistance.

This diverse material compatibility allows us to cater to industries ranging from automotive and aerospace to bespoke manufacturing.

End-to-End Solutions for Metal Parts Manufacturing

Integrated metal fabrication services

CNC turning is one of many fabrication services we offer, providing comprehensive solutions for metal parts manufacturing. By integrating these services, we deliver a streamlined, end-to-end solution that saves time, reduces costs, and ensures consistent quality tailored to your project requirements.

Steel laser cutting

We offer precise and efficient steel laser cutting, perfect for producing intricate shapes with minimal waste.

Punched metal parts

Our punching services deliver high-speed production of metal parts, ensuring consistency across both small and large volumes.

Metal folding

Our metal folding services create precise bends in sheet metal, supporting designs that require clean angles and accurate dimensions.

Welding

Our expert welding ensures strong, durable joins, whether for small projects or large-scale assemblies.

Robotic welding

Robotic welding delivers a high level of accuracy, reliability, and efficiency in our fabrication work.

CNC milling/ machining

CNC milling is a manufacturing process that uses computer-controlled, rotating cutting tools to remove material and shape a workpiece.

Inserting (fasteners)

Inserting fasteners ensures strong, secure connections for durable and reliable assemblies.

Powder coating

Enhance the durability and appearance of your metal products with our professional powder coating services.

Product assembly & kitting

We offer full product assembly and kitting solutions, ensuring your components are delivered ready for use or sale.

Bespoke metal pressing

Our custom metal pressings provide tailored solutions that require consistency in high-volumes.

Metal tube bending

With our tube bending services, we create smooth and exact curves in metal tubing, ideal for structural and functional applications.

Discuss Your CNC Turning Requirements with Our Experts

Contact us for CNC turning services

For projects requiring high-precision CNC turning, our team is equipped with advanced lathes, technical expertise, and a commitment to delivering reliable results. Contact us today to learn more about how our CNC turning services can support your specific project needs with accuracy and efficiency.