Delivering Precision Laser Cutting for a Range of Metal Types

CNC laser cutting & metal fabrication services

Optimised Solutions for Diverse Projects

Precision

laser cutting services

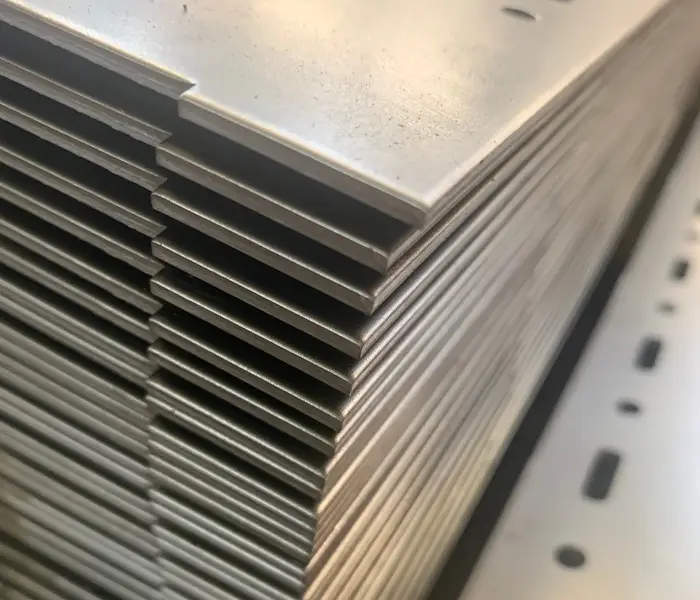

Our laser cutting services are designed to deliver high-precision, efficient results for a range of metal types. Using state-of-the-art CNC laser cutting technology, we provide solutions that meet the diverse demands of industrial, commercial, and architectural projects. The process focuses on accuracy and optimised material use, enabling design goals to be achieved with reliability and efficiency in every project.

High-Speed Laser Cutting Technology for Complex & Large-Scale Projects

Advanced laser cutting

capabilities & specifications

Our laser cutting capabilities utilise advanced technology to support projects of varying complexity. With capability to cut up to 20mm thick and speeds reaching 100 metres per minute, the Amada fibre laser system allows us to handle both detailed cuts and large-scale production efficiently. An automated 12-tonne capacity feed tower enhances workflow by storing multiple sheet types and thicknesses, ensuring consistent flow and minimised downtime for high-demand projects.

We also employ the Amada C1 punch-laser combination machine, which integrates turret punching with laser cutting in a single process. This combination offers efficiency and flexibility, making it suitable for projects that require both precision cutting and hole-punching, all within a streamlined process that reduces lead times.

Machine Specifications

Amada Fibre Laser (LCG 3015 AJ)

Sheet Size

3000 x 1500mm

Thickness

0.5 to 20mm

Materials

Mild steel, Stainless steel, Aluminium, Yellow metals, Galvanised steel/ Zintec, Titanium

Amada Laser-Punch Combination (LC 2012 C1)

Sheet Size

2500 x 1250mm

Thickness

0.5 to 6mm

Materials

Mild steel, Stainless steel, Aluminium, Yellow metals, Galvanised steel/ Zintec, Titanium

High-Speed, High-Precision Laser Cutting Solutions

Advanced CNC laser cutting capabilities

At Aldermans, our state-of-the-art CNC laser cutting equipment ensures precision and efficiency for diverse applications. Utilising advanced machinery, we support the production of custom metal parts with consistent quality and cost-effective solutions, without compromising accuracy.

Amada LCG 3015 AJ

The Amada LCG 3015 AJ is a high-performance fibre laser cutting machine, offering exceptional precision and speed. With a working range of 3070 x 1550 mm and laser power options up to 4 kW, it handles a variety of materials and thicknesses with ease. Equipped with the AMNC 3i control system and automatic sheet loading, it ensures efficient operation and reduced lead times.

Amada LC 2012 C1 NT

The Amada LC 2012 C1 NT combines punching and laser cutting capabilities in a single machine, enhancing versatility and productivity. Featuring a 1.2KW Co2 laser and a 46-station turret with tapping units, it efficiently processes complex parts. The integrated automatic sheet loader and brush table system minimise manual handling and protect material surfaces during processing

Versatile Metal Options for Industrial & Commercial Applications

Materials available for

laser cutting & custom fabrication

Mild steel

Strong and versatile, used in structural applications and general fabrication. Cutting thickness: 0.5mmTH to 20mmTH

Stainless steel

Corrosion-resistant, ideal for kitchens, medical tools, and outdoor structures. Available in polished or dull finish, in 430, 304, or 316 grades. Cutting thickness: 0.5mmTH to 15mmTH

Aluminium

Lightweight and durable, perfect for aerospace, automotive, and electronics. Cutting thickness: 0.5mmTH to 12mmTH

Yellow metals

Includes materials such as brass and bronze, commonly used for decorative and functional applications requiring high durability. Cutting thickness: 0.5mmTH to 8mmTH

Galvanised steel / zintec

Corrosion-protected, commonly used in construction and HVAC systems. Galv available in up to 5mm and Zintec up to 3mm.

Titanium

Lightweight and strong, ideal for specialised applications. Cutting thickness: 0.5mmTH to 8mmTH

Reducing Waste & Maximising Efficiency with CNC Profiling

Optimised material use with

CNC profiling technology

Our CNC profiling software is designed to optimise material utilisation, reducing waste and ensuring cost-effective production. We can process parts from a variety of input media, including 3D models, and offer punched holes with a wide selection of patterns and shapes to match each project’s unique design.

Additional Fabrication Services: Folding, Welding, & Powder Coating

Integrated metalworking services

Punched metal parts

Our punching services deliver high-speed production of metal parts, ensuring consistency across both small and large volumes.

Metal folding

Our metal folding services create precise bends in sheet metal, supporting designs that require clean angles and accurate dimensions.

Welding

Our expert welding ensures strong, durable joins, whether for small projects or large-scale assemblies.

Robotic welding

Robotic welding delivers a high level of accuracy, reliability, and efficiency in our fabrication work.

CNC turning

Achieve precision and accuracy with our CNC turning, ideal for producing complex metal components with tight tolerances.

CNC milling/ machining

CNC milling is a manufacturing process that uses computer-controlled, rotating cutting tools to remove material and shape a workpiece.

Inserting (fasteners)

Inserting fasteners ensures strong, secure connections for durable and reliable assemblies.

Powder coating

Enhance the durability and appearance of your metal products with our professional powder coating services.

Product assembly & kitting

We offer full product assembly and kitting solutions, ensuring your components are delivered ready for use or sale.

Bespoke metal pressing

Our custom metal pressings provide tailored solutions that require consistency in high-volumes.

Metal tube bending

With our tube bending services, we create smooth and exact curves in metal tubing, ideal for structural and functional applications.

Find Out How Our Laser Cutting Services Can Support Your Project

Contact us for expert metal cutting & fabrication solutions

Our laser cutting service is structured around your project requirements, delivering solutions that balance precision, speed, and flexibility. Whether you need complex patterns, high-volume production, or optimised material use, our team is ready to support you with expertise and advanced technology. Contact us to discuss how we can meet your project goals with reliable, efficient, and tailored laser cutting services.