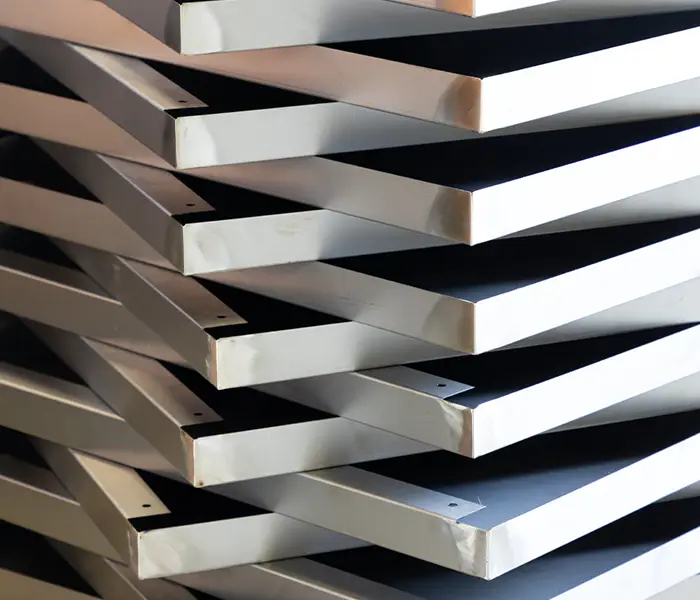

Expert Solutions for Accurate Sheet Metal Folding & Bending

Precision metal folding services

Custom Forms with Accuracy & Consistency

Precision

metal folding services

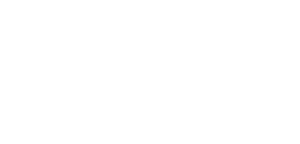

Our metal folding services provide precise, high-quality solutions for projects across a range of industries. With advanced equipment and skilled technicians, we create custom, complex forms in sheet metal to meet the unique requirements of each project. Our process ensures accuracy and repeatability in every component.

Industry-Leading Equipment for Complex Metal Folding

Advanced metal folding

capabilities & technical specifications

Our facility is equipped with cutting-edge technology, allowing us to perform CNC-controlled folding. This versatility ensures we can handle complex projects with precision and efficiency.

Press brakes for sheet

metal folding

Our range of state-of-the-art press brakes are capable of handling various metals and sheet thicknesses. This advanced machinery is used to achieve precise folds tailored to specific designs, with accuracy and repeatability. With capabilities including lengths up to 3m and a maximum tonnage of 170T, our equipment supports a wide range of metal folding applications.

Precision Sheet Metal

Forming

Forming with press brakes allows us to create accurate bends and complex shapes across a variety of profiles. Our CNC-controlled equipment ensures each fold is precisely executed, supporting both functional and aesthetic requirements in metal components.

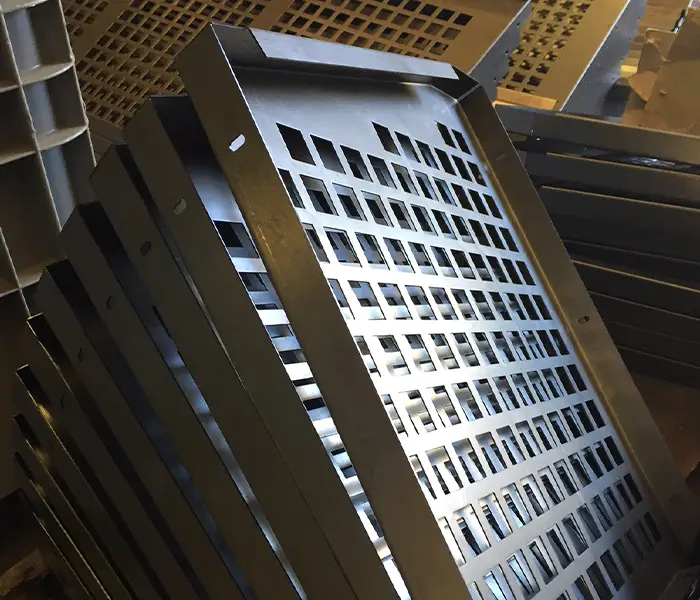

Reliable Folding for

High-Volume Projects

Our press brake systems are well-suited to both low- and high-volume production runs. With programmable folding sequences and tool changes, we can maintain tight tolerances and repeatability even when producing large batches of formed sheet metal parts.

High-Performance Folding with Advanced AMADA Equipment

Our press brake technology

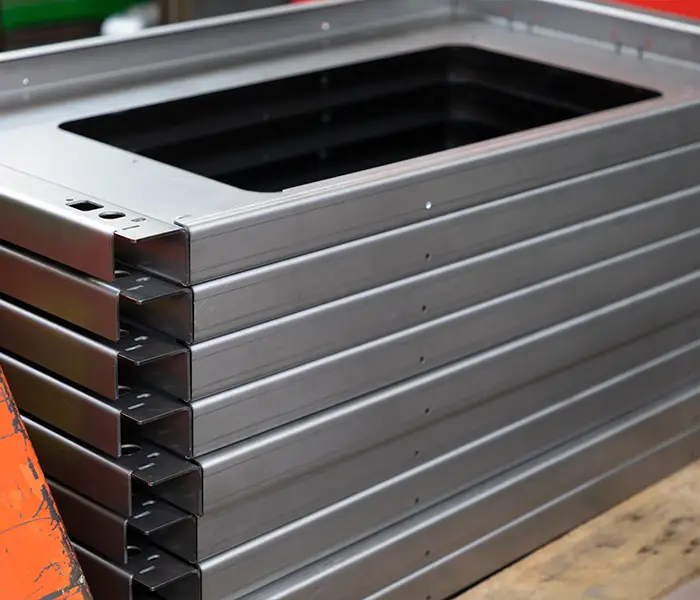

At Aldermans, we operate five press brakes from the AMADA HFE3i series, each designed to meet a broad spectrum of metal folding requirements. These high-specification hydraulic machines offer enhanced control, accuracy, and reliability, supporting consistent results across both simple and complex folded components.

The HFE3i range combines robust build quality with smart interface technology, allowing for greater productivity and precise repeatability. With touchscreen controls and user-friendly programming features, our team can quickly set up and adjust jobs to maintain tight tolerances. The models in use – 50, 100, 130, and 170 tonne variants – provide flexibility for a range of part sizes and material thicknesses.

This investment in modern press brake technology not only increases our folding capacity but also ensures energy efficiency, stability in output, and high-quality results – even on large-scale production runs.

Rigorous Inspections for Precision & Consistency

Quality control in CNC metal folding & forming

Quality is integral to our metal folding process, with each project undergoing comprehensive inspection stages to ensure precision and consistency, guaranteeing that every component meets exact specifications for reliable performance across all applications.

First-off inspection for metal folding precision

In-process inspection for consistent quality

Post-process quality inspection for final verification

From Folding to Finishing: Full Metal Fabrication Solutions

Integrated metal fabrication services

Our metal folding services are part of a full-spectrum fabrication solution, encompassing sheet metal profiling, bending, welding, and finishing to provide a seamless, one-stop shop for metalwork needs. By integrating these capabilities under one roof, we streamline production, ensuring an efficient, cost-effective, and timely project delivery.

Steel laser cutting

We offer precise and efficient steel laser cutting, perfect for producing intricate shapes with minimal waste.

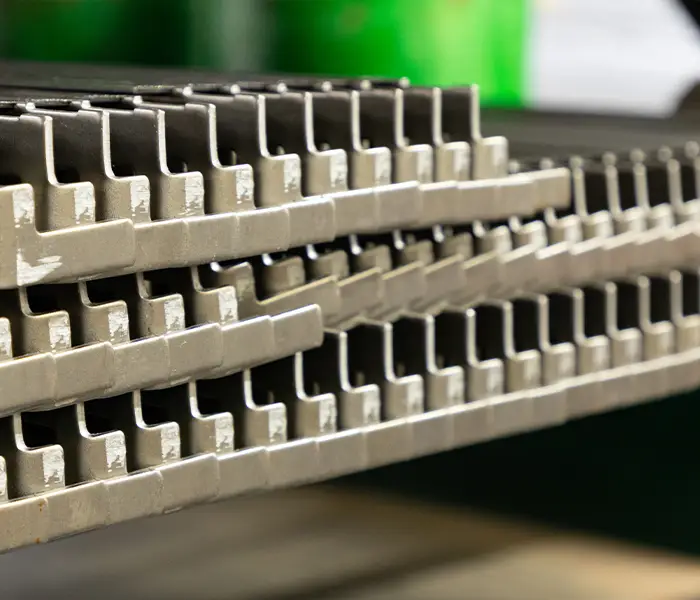

Punched metal parts

Our punching services deliver high-speed production of metal parts, ensuring consistency across both small and large volumes.

Welding

Our expert welding ensures strong, durable joins, whether for small projects or large-scale assemblies.

Robotic welding

Robotic welding delivers a high level of accuracy, reliability, and efficiency in our fabrication work.

CNC turning

Achieve precision and accuracy with our CNC turning, ideal for producing complex metal components with tight tolerances.

CNC milling/ machining

CNC milling is a manufacturing process that uses computer-controlled, rotating cutting tools to remove material and shape a workpiece.

Inserting (fasteners)

Inserting fasteners ensures strong, secure connections for durable and reliable assemblies.

Powder coating

Enhance the durability and appearance of your metal products with our professional powder coating services.

Product assembly & kitting

We offer full product assembly and kitting solutions, ensuring your components are delivered ready for use or sale.

Bespoke metal pressing

Our custom metal pressings provide tailored solutions that require consistency in high-volumes.

Metal tube bending

With our tube bending services, we create smooth and exact curves in metal tubing, ideal for structural and functional applications.

Discuss Your Metal Folding Requirements with Our Team

Contact us for expert metal folding & forming services

For projects requiring precision metal folding and forming, our team is equipped with the skills, technology, and expertise to deliver reliable, consistent results. Contact us today to discuss your requirements and find out how we can support your project with high-quality, efficient metal fabrication services