High-Quality Sheet Metal Punching Solutions Tailored to Your Needs

Precision punched metal parts services

Efficient & Precise

Advanced punching for

custom designs & high-volume

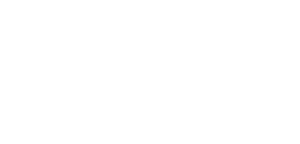

Metal punching services offer an efficient and cost-effective solution for producing precision components. Utilising advanced turret punching technology, this process ensures accurate results for projects requiring custom patterns, intricate shapes, or high-volume production. With capabilities designed to deliver speed, consistency, and reliability, metal punching is an essential method for manufacturing high-quality components across various industries.

High-Speed, High-Accuracy Solutions for Complex Metal Designs

Advanced CNC punching

capabilities

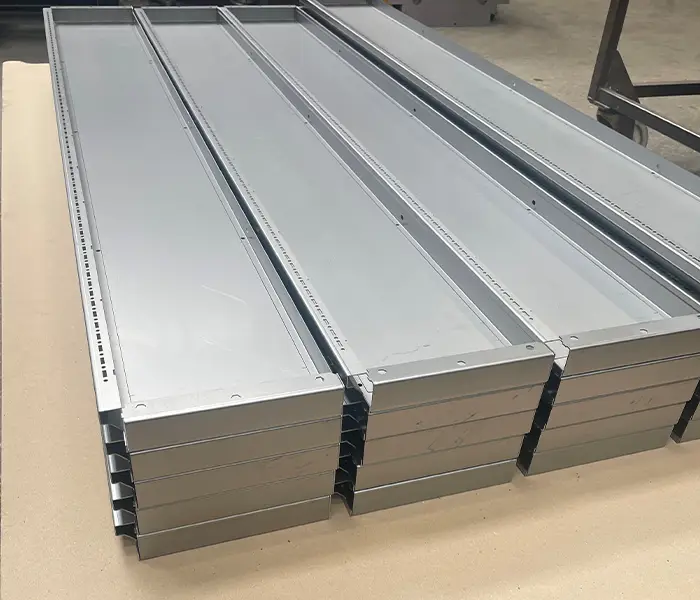

State-of-the-art CNC punching equipment, including the Amada EMZ Turret Punch and the Amada C1 Punch-Laser Combination Machine, ensures precision and efficiency for diverse applications, supporting the production of custom metal parts with consistent quality and cost-effective solutions without compromising accuracy.

Amada EMZ Turret Punch

Capable of producing intricate punching patterns and shapes at high speeds, this machine is ideal for large-scale projects.

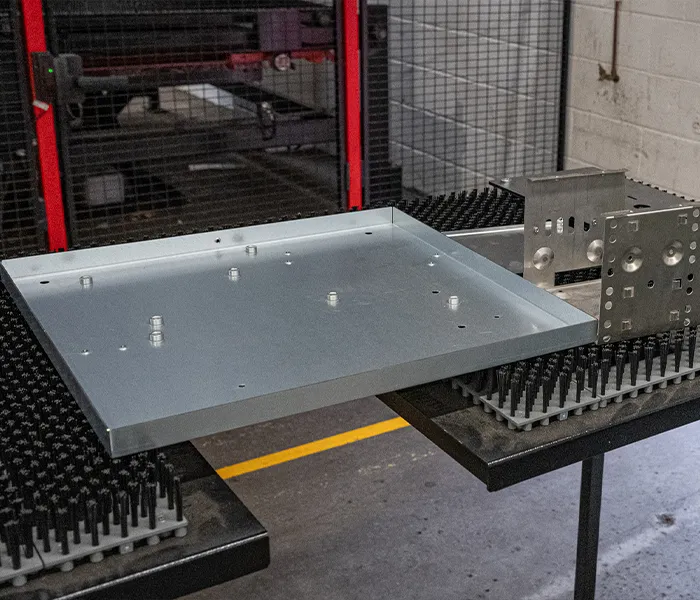

Amada C1 Punch-Laser Combination Machine

Combining punching and laser cutting in a single process, this machine provides flexibility for projects requiring multiple fabrication techniques.

Automatic Sheet Loader

Enables continuous operation for high-volume production, enhancing efficiency and reducing lead times.

machine specifications

EM-MII series

Sheet Size

3000 x 1500mm

Thickness

up to 6mm

Materials

Mild Steel, Stainless Steel, Aluminium and Yellow Metals

Precision, Versatility, & Efficiency in Metal Fabrication

Benefits of

punched metal parts

Punched metal parts offer a combination of precision, durability, and cost efficiency, making them an ideal choice for industrial and commercial applications. Their ability to create complex patterns and forms perforations provides design flexibility for meeting specific project requirements.

The machinery can process sheet metal measuring 3050 x 1525mm without the need for repositioning. This significantly reduces processing times and increases efficiency.

Specialist CNC punching software maximises material usage, reducing waste and lowering production costs, while maintaining structural integrity for demanding environments. Suitable for industries ranging from retail and manufacturing to architecture, punched components offer adaptability, ensuring they fulfil functional and aesthetic demands across projects of any scale.

Ensuring Excellence Through Precision and Attention to Detail

Quality assurance in punched metal parts

Every punched metal part undergoes stringent quality control measures to ensure precision and reliability at every stage, guaranteeing that each component meets exact specifications and delivers consistent performance across all applications.

First-off inspection

In-process monitoring

Post-production verification

A Comprehensive Solution for Metal Fabrication Projects

Integrated metal fabrication services

Punched metal parts form a key part of an integrated metal fabrication offering. By combining these capabilities, we deliver a complete solution that ensures streamlined production and consistent quality at every stage.

Steel laser cutting

We offer precise and efficient steel laser cutting, perfect for producing intricate shapes with minimal waste.

Metal folding

Our metal folding services create precise bends in sheet metal, supporting designs that require clean angles and accurate dimensions.

Welding

Our expert welding ensures strong, durable joins, whether for small projects or large-scale assemblies.

Robotic welding

Robotic welding delivers a high level of accuracy, reliability, and efficiency in our fabrication work.

CNC turning

Achieve precision and accuracy with our CNC turning, ideal for producing complex metal components with tight tolerances.

CNC milling/ machining

CNC milling is a manufacturing process that uses computer-controlled, rotating cutting tools to remove material and shape a workpiece.

Inserting (fasteners)

Inserting fasteners ensures strong, secure connections for durable and reliable assemblies.

Powder coating

Enhance the durability and appearance of your metal products with our professional powder coating services.

Product assembly & kitting

We offer full product assembly and kitting solutions, ensuring your components are delivered ready for use or sale.

Bespoke metal pressing

Our custom metal pressings provide tailored solutions that require consistency in high-volumes.

Metal tube bending

With our tube bending services, we create smooth and exact curves in metal tubing, ideal for structural and functional applications.

Discuss Your Punched Metal Parts Requirements Today

Contact us for precision metal punching services

CNC punching services are tailored to meet the demands of precision, efficiency, and cost-effectiveness. Whether custom patterns, large-scale production, or multi-functional metal parts are required, advanced equipment and expertise ensure exceptional results. Contact the team today to explore how punched metal parts can support your next project with reliable and high-quality solutions.