Consistent, Clean Welds at Scale

Robotic welding

Quality, Speed & Efficiency in MIG Fabrication

Robotic

welding excellence

Robotic welding delivers a high level of accuracy, reliability, and efficiency in our fabrication work. Ideal for mid- to high-volume production, supports faster throughput, excellent repeatability, and dependable weld strength across a wide range of materials and applications. By automating the MIG welding process, Aldermans can achieve high-quality results with reduced lead times and enhanced cost-effectiveness.

How Aldermans Delivers Precision with Automation

What is

robotic welding?

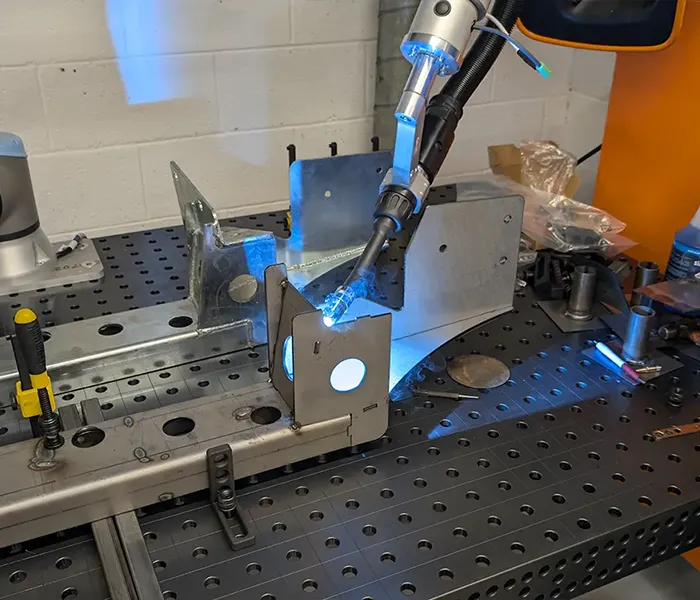

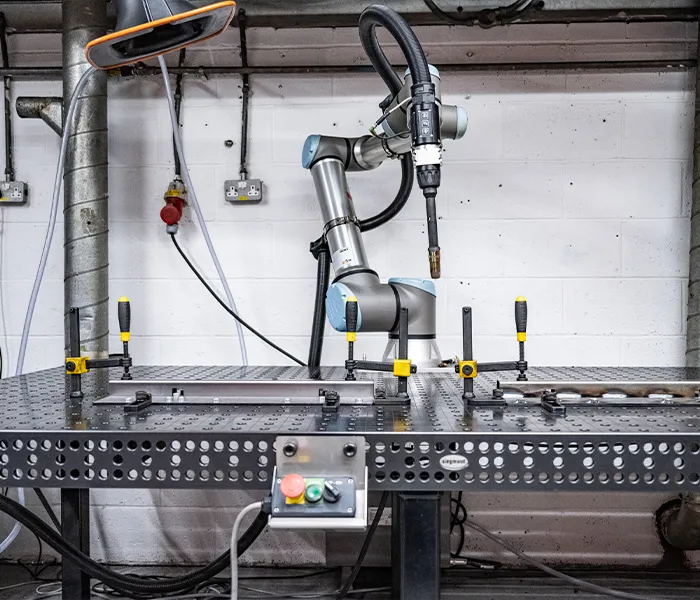

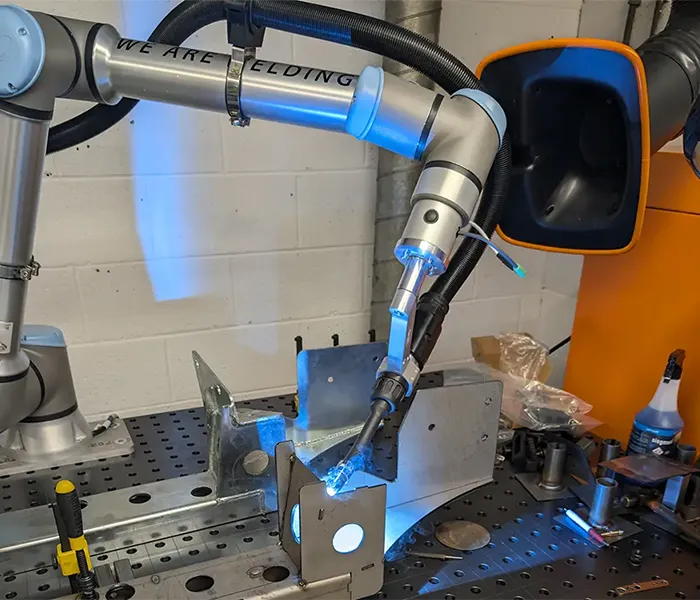

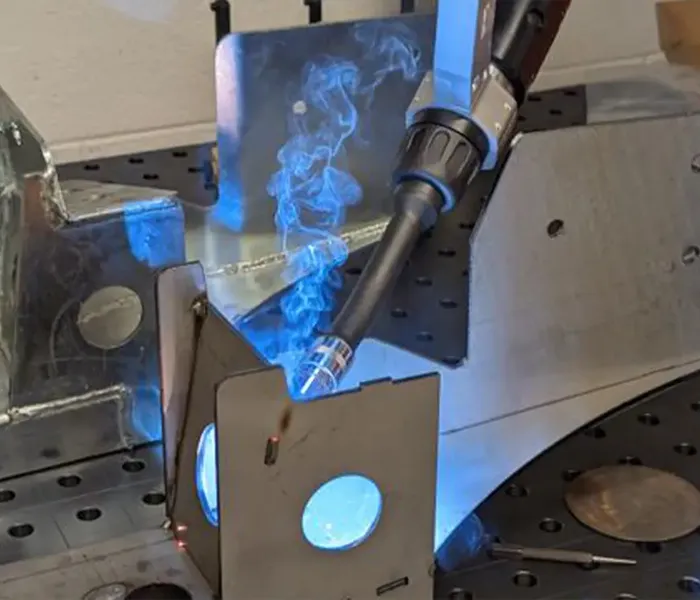

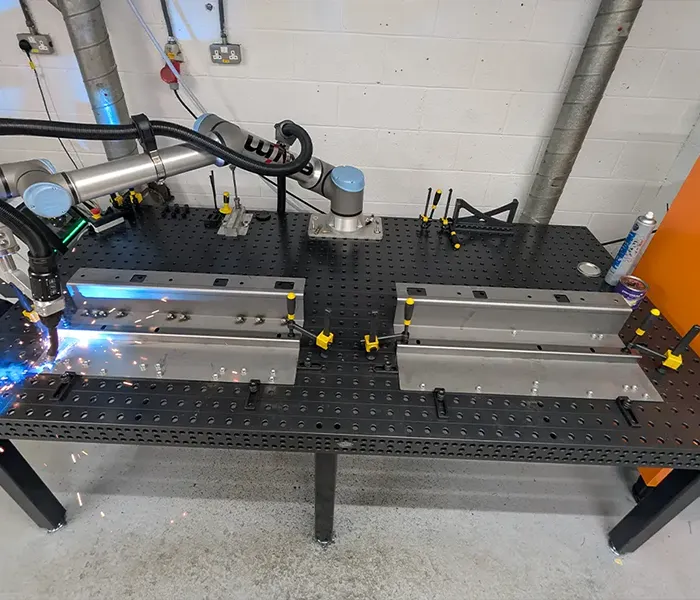

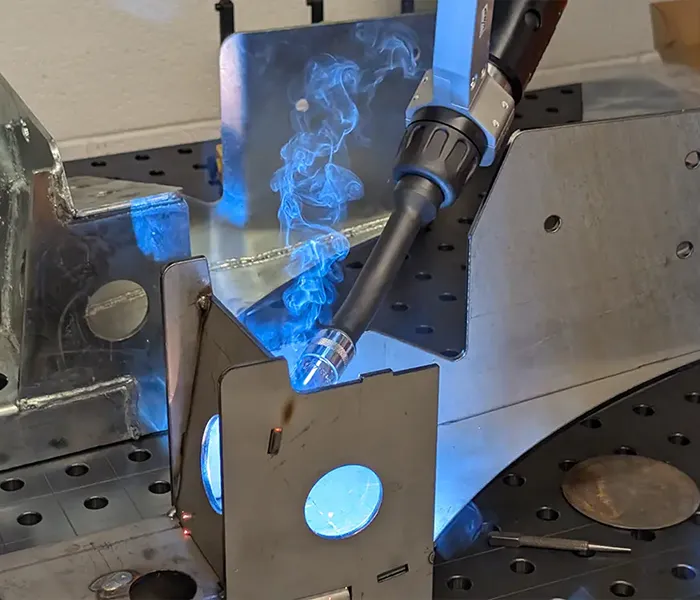

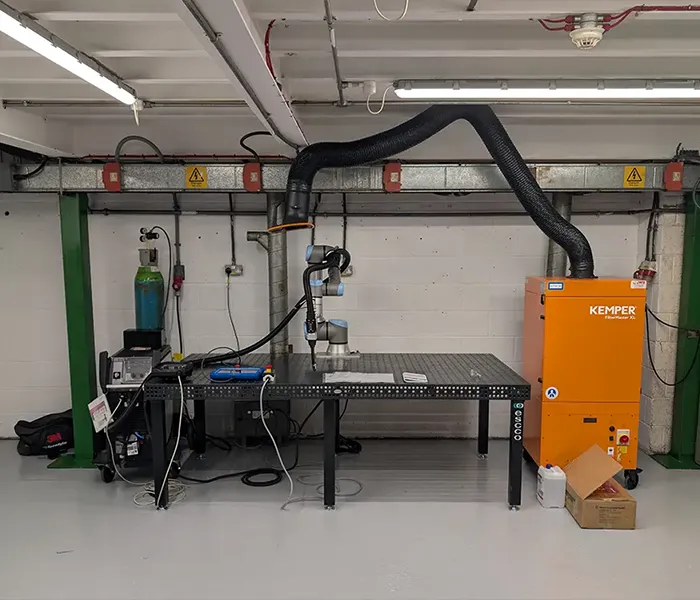

Robotic welding is an automated process that employs a collaborative robotic arm to produce MIG welds to a consistent standard. At Aldermans, our robotic welding cell integrates the Universal Robots UR10e arm with the EWM Titan XQ 400 Puls welding plant, one of the most advanced MIG systems available. The cell is programmed using SmoothTool software, enabling quick setup through a teaching pendant and point-to-point interface.

This setup enables the delivery of consistent, high-quality welds with minimal variation. Robotic welding is typically used as part of a broader fabrication project, but can be commissioned as a standalone service for jobs involving suitable batch quantities or regular production runs.

wide variety of components & materials

Capabilities & applications

Our robotic welding system is designed to handle a wide variety of components and materials that require consistent weld quality across large production volumes.

Material compatibility:

Mild steel, stainless steel, and aluminium

Weld types:

Fillet, butt, tack, plug, and pipe welds

Weld speed:

400mm per minute

Air movement speed:

1000mm per second

Robot reach:

1300mm, allowing for larger or more awkward components

Efficiency:

Fast setup and rapid changeover for high-mix production

Batch production:

Multi-part jig welding to reduce handling and downtime

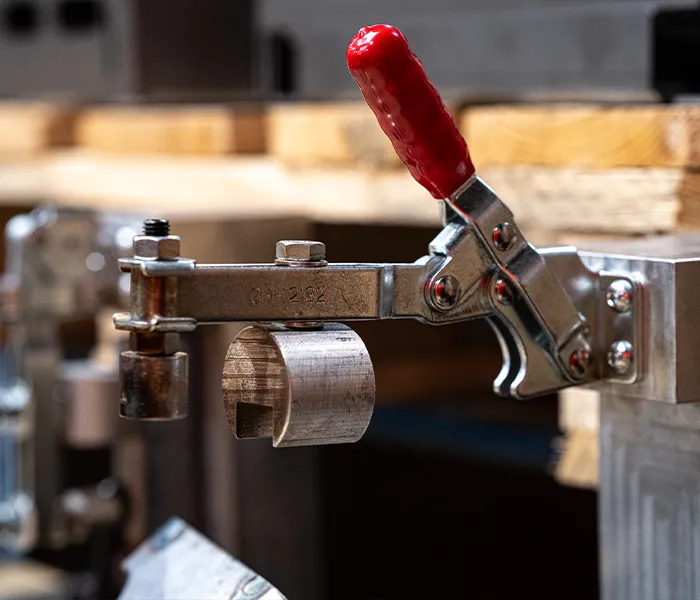

Jig design:

In-house design and manufacture of fixtures for complex components

the process

How robotic welding works

Part setup & fixturing

Once parts have been fabricated using our other in-house processes, they are then transferred to our robotic welding cell. Depending on the component, items are either fixtured directly onto our Siegmund Extreme 8.7 welding table or secured in a custom jig designed for multi-item setups.

Programming the robotic arm

The robotic arm is then guided by the operator using the SmoothTool teaching interface. Each weld path is manually set via a teaching pendant, allowing the software to store exact movement instructions. Once programmed, the robot consistently repeats these welds on all subsequent parts.

Quality control & production

Before production begins, we conduct an initial quality control inspection to verify alignment and dimensions. Once approved, the programme is locked, and the robot operates continuously. When necessary, additional inspections can be scheduled at timed or quantity-based intervals.

Optimised Solutions for Diverse Projects

Why choose

aldermans for robotic welding?

We adopted robotic welding to address the increasing demand for clean, repeatable welds in batch production. By combining collaborative automation with in-house fixture design, we can streamline preparation time and enhance overall process efficiency.

Robotic welding offers:

- Reliable quality: Repeatable welds across all units

- Increased throughput: Less downtime between parts

- Cleaner finishes: Strong, precise welds every time

- Cost-effective runs: Particularly on repeat jobs or standardised assemblies

Our team will evaluate each component to determine if robotic welding is the most suitable method. We can offer advice on fixture choices, production volumes, and possible efficiencies.

Additional metalworking Services: Folding, Welding, & Powder Coating

Integrated metalworking services

Steel laser cutting

We offer precise and efficient steel laser cutting, perfect for producing intricate shapes with minimal waste.

Punched metal parts

Our punching services deliver high-speed production of metal parts, ensuring consistency across both small and large volumes.

Metal folding

Our metal folding services create precise bends in sheet metal, supporting designs that require clean angles and accurate dimensions.

Welding

Our expert welding ensures strong, durable joins, whether for small projects or large-scale assemblies.

CNC turning

Achieve precision and accuracy with our CNC turning, ideal for producing complex metal components with tight tolerances.

CNC milling/ machining

CNC milling is a manufacturing process that uses computer-controlled, rotating cutting tools to remove material and shape a workpiece.

Inserting (fasteners)

Inserting fasteners ensures strong, secure connections for durable and reliable assemblies.

Powder coating

Enhance the durability and appearance of your metal products with our professional powder coating services.

Product assembly & kitting

We offer full product assembly and kitting solutions, ensuring your components are delivered ready for use or sale.

Bespoke metal pressing

Our custom metal pressings provide tailored solutions that require consistency in high-volumes.

Metal tube bending

With our tube bending services, we create smooth and exact curves in metal tubing, ideal for structural and functional applications.

Find Out How Our Robotic Welding Services Can Support Your Project

Contact us for discuss your robotic welding requirements

Looking for clean, repeatable welds for your next project? Our robotic welding cell is ideal for batch production and complex assemblies. We’ll assess your part and advise on the best solution to meet your requirements.

Get in touch to see how robotic welding can support your fabrication needs.