High-Quality Solutions for Complex Metal Shaping Needs

Precision welding services

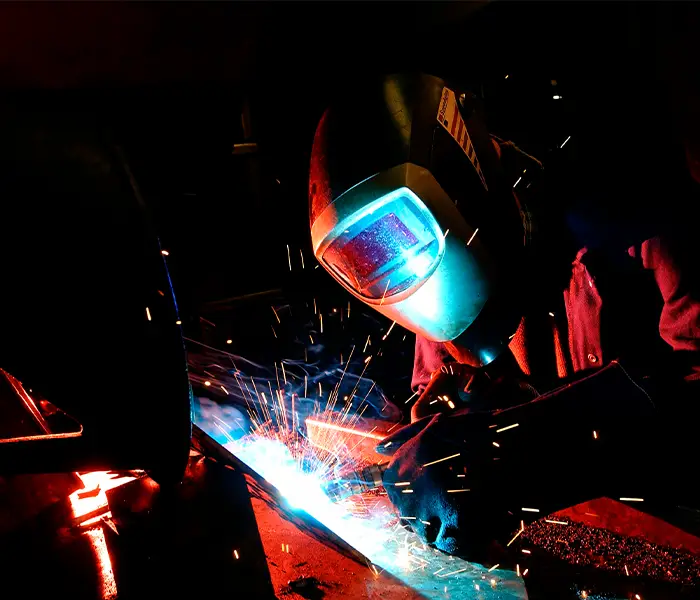

MIG, TIG, Spot, & Stud Welding for Reliable Metal Assemblies

Expert welding services

Our welding services utilise MIG, TIG, spot, and stud welding techniques to deliver strong, precise metal joins for a wide range of industries. Each method is chosen to suit the specific material and application, ensuring robust assemblies and components. Working with aluminium, mild steel, and stainless steel, we produce durable welds that reflect the highest standards of workmanship.

Reliable Methods for Diverse Metal Fabrication Needs

Advanced welding techniques applications

Our welding processes employ advanced equipment and techniques to meet the unique demands of each project:

MIG welding

Metal Inert Gas (MIG) welding uses a continuous wire feed into the weld pool, allowing for high material deposition. It is well-suited to welding most metal thicknesses. This process enables high travel speeds and is ideal where strength is essential.

Advantages

- Welding speeds significantly quicker than TIG welding

- High material deposition rate allows for larger welds

- Versatile across many different thicknesses

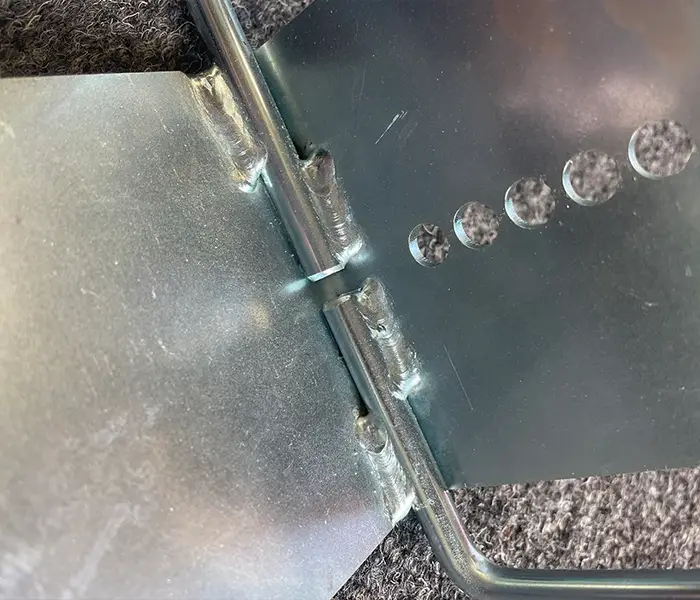

TIG welding

Tungsten Inert Gas (TIG) welding uses a non-consumable tungsten electrode, with the option to manually feed filler material into the weld pool when needed. It is ideal for welding thin to medium-thickness metals. The controlled nature of the process produces clean, precise weld profiles, minimising the need for post-weld dressing and making it particularly suitable for visible joints.

Advantages

- Precise weld profiles can be achieved

- Better heat control can reduce part distortion

- Neater welds require none/minimal dressing

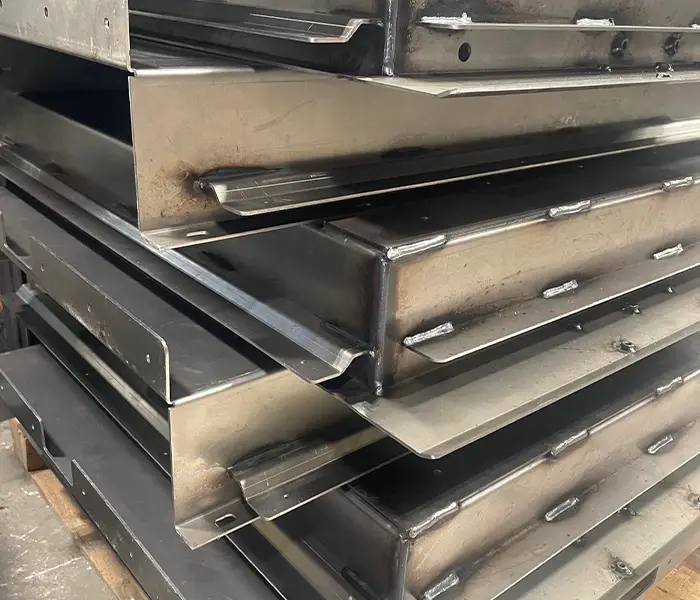

Spot welding

Spot welding uses two non-consumable copper electrodes to pass an electrical current through layered materials while applying pressure. It is ideal for welding thin to medium-thickness metals. The process creates small, circular welds on overlapping components, making it particularly effective in situations where traditional welding techniques are unsuitable.

Advantages

- Joins material together with high speed

- Can join multiple layers of material together in one weld

- Creates strong welds in precise locations

Stud welding

Stud welding uses an electrical current to weld specialised fasteners directly to metal surfaces. It is suitable for all material thicknesses. The process allows fasteners to be securely attached in locations where conventional fixings may not be appropriate—particularly when the reverse side of the fastener is visible.

Advantages

- Fasteners not visible from opposing side

- No need to access opposing side when fixing

- Wide range of fasteners available

Each technique is meticulously selected to match the material properties and functional requirements of the project. By combining the right method with our expertise, we ensure optimal results for every join.

Precision & Consistency for High-Quality Results

Accuracy in welding processes

Our welding services offer exceptional accuracy, with tolerances ranging specific to each design with accuracy of up to +/-0.2mm depending on the application. This level of precision provides repeatable results, making it ideal for projects with strict quality demands. For larger production batches, we create custom welding jigs that ensure components are aligned perfectly during each weld. These jigs improve both speed and consistency, ensuring high-quality results across every piece.

Ensuring Strength, Durability, & Consistency

Quality control in welding services

Our welding services adhere to stringent quality control measures to ensure high performance and reliability:

In-process monitoring

first-off inspection

Post-weld evaluation

These rigorous inspections, combined with our precision welding tolerances and custom jigs, ensure every weld delivers the durability, strength, and accuracy required for even the most complex applications.

From Cutting to Finishing: Tailored Solutions for Every Project

Integrated metal fabrication services

In addition to our precision welding services, we offer a range of versatile metal fabrication solutions designed to meet diverse project requirements. By combining these services with our welding capabilities, we provide a streamlined, end-to-end solution that ensures high-quality results across all stages of the fabrication process.

Steel laser cutting

We offer precise and efficient steel laser cutting, perfect for producing intricate shapes with minimal waste.

Punched metal parts

Our punching services deliver high-speed production of metal parts, ensuring consistency across both small and large volumes.

Metal folding

Our metal folding services create precise bends in sheet metal, supporting designs that require clean angles and accurate dimensions.

Robotic welding

Robotic welding delivers a high level of accuracy, reliability, and efficiency in our fabrication work.

CNC turning

Achieve precision and accuracy with our CNC turning, ideal for producing complex metal components with tight tolerances.

CNC milling/ machining

CNC milling is a manufacturing process that uses computer-controlled, rotating cutting tools to remove material and shape a workpiece.

Inserting (fasteners)

Inserting fasteners ensures strong, secure connections for durable and reliable assemblies.

Powder coating

Enhance the durability and appearance of your metal products with our professional powder coating services.

Product assembly & kitting

We offer full product assembly and kitting solutions, ensuring your components are delivered ready for use or sale.

Bespoke metal pressing

Our custom metal pressings provide tailored solutions that require consistency in high-volumes.

Metal tube bending

With our tube bending services, we create smooth and exact curves in metal tubing, ideal for structural and functional applications.

Speak to Our Team About Your Welding Requirements

Contact us for welding & fabrication services

For projects requiring MIG, TIG, spot, or stud welding, we provide tailored solutions to meet your exact specifications. Contact us to learn more about our welding capabilities and how we can help you achieve reliable, efficient results for your fabrication needs.