In the third of our Carbon Net Zero articles, Managing Director Karen Friendship explores how businesses need to support each other in the CNZ quest.

Saturday 22nd April was Earth Day 2023; so it’s an appropriate time for us to reflect again on our own journey towards Carbon Net Zero.

Earth Day began in 1970 – it’s been around for almost as long as Aldermans! It began as a coalition of multiple environmental causes, uniting around common values. This reminds us that there are many ways to make a positive environmental impact; but finding alignment adds strength to voices and generates traction. As chair of the Plymouth Manufacturers’ Group, I see members sharing their own experiences and discoveries, helping each other to consider the whole supply chain impact of decisions and efforts.

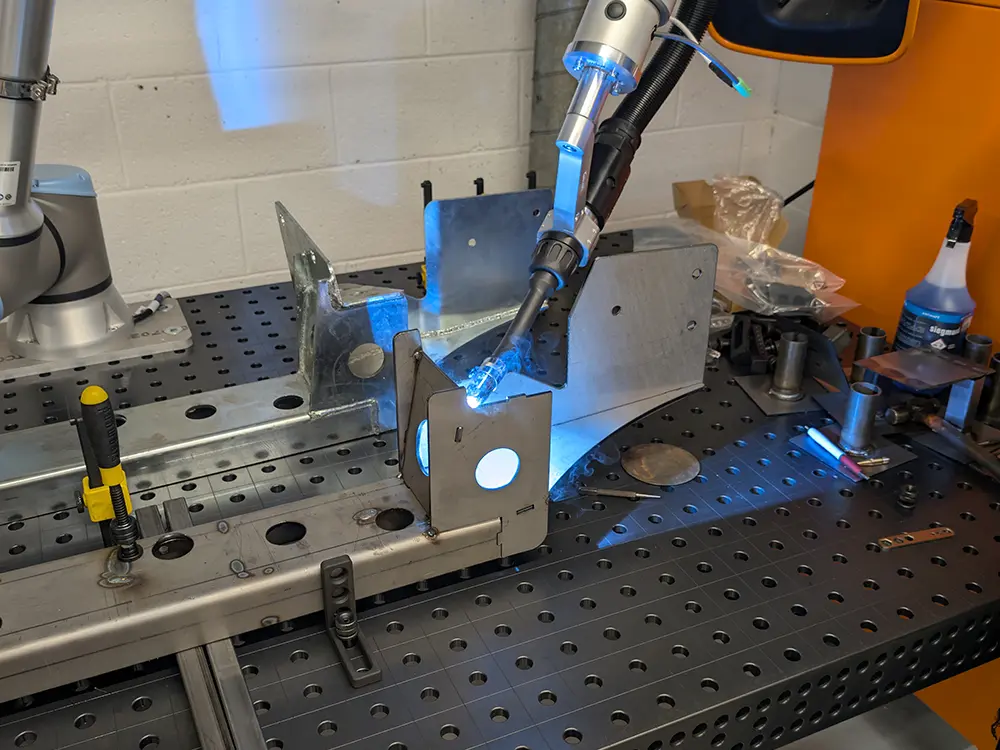

At the Aldermans factory, like many businesses, we are seeing energy costs soar from 1st April, due to changes in government support. This means we need to fund an additional £6,000 of energy costs per month. It’s already changed our behaviour, as we realise that the cost of running machines on certain shifts now exceeds the revenue generated. The challenging economics are becoming a driver for efficiency, and for reconsidering our whole working pattern. This could mean less weekend and evening work, which may hopefully have a positive impact on the work-life balance for our staff, too.

Rationalising energy use will only take us so far. Taking control of our energy generation has to be a factor, particularly as we are an intensive user. So, we are excited to be on the brink of installing an extension to our rooftop solar array (as shown in the visualisation below). This will add 270kW to our generation capacity – all of which the factory will easily consume. It requires an investment of around £250,000, and the payback time will be 3 to 4 years. The challenge for smaller businesses of course is to fund such capital projects when faced with all-round rising costs.

Nonetheless, we are feeling confident that we will achieve Carbon Net Zero for Scope 1 and Scope 2 by 2030. Scope 3, however, is the bigger concern. As you’d expect, we purchase tonnes of steel, and when this enters the factory we have to take responsibility for the carbon, right back to its source. If we buy from suppliers who are not Carbon Net Zero, then the carbon responsibility is transferred to us. All of this will take some considerable calculation; and transparency is vital if there is going to be any genuine impact. ‘Greenwash’ will not wash!

Logically, as a small manufacturer, we are strongly dependent on major suppliers also progressing towards Carbon Net Zero at the same pace as ourselves, and communicating clearly about their progress. If they do not, then the embedded carbon load will hinder our own ability to achieve net zero… which in turn may hinder our customers’ net zero efforts. As partners in a business ecosystem, supply chain alignment is vital. All companies need to take responsibility, together, for doubling-down on their environmental efforts.