Plessey- Lighting Casing

The requirement

Travel north out of Plymouth, and you cannot fail to see the headquarters of Plessey Semiconductors Ltd at Roborough, on the edge of Dartmoor National Park. Built in the 1980s, this landmark building is home to a company with a 100-year history of innovation, internationally respected for its semiconductor manufacturing capabilities.

Plessey’s mission is to enhance people’s lives by applying its leading-edge technologies to healthcare sensor solutions, integrated and intelligent GaN-on-Silicon solid-state lighting, and horticultural lighting applications. The company has won numerous awards for its innovation and efficiency, particularly in reducing the cost while improving the efficacy of LED lighting using standard silicon manufacturing techniques.

One of Plessey’s key developments, the Hyperion™ LED lighting system, was designed to improve efficiency in commercial food production. As consumers increasingly expect fresh fruit and vegetables year-round, growers must extend seasonality, improve crop yields, and enhance flavour, all while keeping energy costs under control. The Hyperion™ system offers lower energy consumption than traditional high-pressure sodium (HPS) lights, reduces the shadowing effect in greenhouses, and provides customisable light spectrums that can be adapted for different crops.

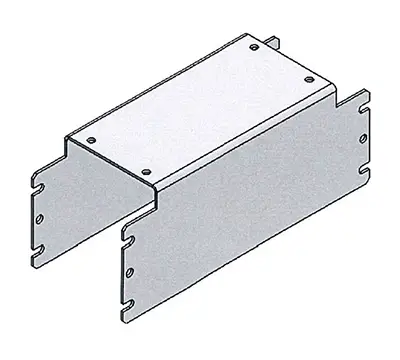

In August 2017, Plessey approached Aldermans to manufacture a metal casing as part of the Hyperion™ lighting assembly. This casing was required for a 20,000m² greenhouse extension project at a major Belgian lettuce grower. The project aimed to boost the total cultivation area to 49,000m² using a unique conveyor system that moves plants beneath the LED lights over a five-to-six-week cycle. With tight deadlines to meet, Plessey needed a trusted manufacturing partner capable of delivering precision-engineered parts at scale within a short timeframe.

The solution

Aldermans had already established a working relationship with Plessey in 2015 through their joint involvement in the Plymouth Manufacturers’ Group. This familiarity allowed both teams to collaborate efficiently in developing the new component. The project began with Aldermans creating technical drawings in Solidworks, leading to the production of a prototype for approval.

Once the design was finalised, laser cutting was the first stage of manufacturing. Using Aldermans’ Amada Fibre Laser, the flat metal parts were cut with precision, ensuring maximum material utilisation and reducing waste. The automated ASLUL tower system fed sheet materials into the laser machine, allowing for ‘lights-out’ production—a process where manufacturing continues unattended overnight, significantly improving efficiency and lead times.

After laser cutting, the parts were transferred to Aldermans’ press shop, where they were shaped using CNC press brakes to achieve the required dimensions and tolerances. By leveraging automated technology and highly skilled staff, Aldermans ensured that production remained on schedule without compromising on quality.

The outcome

Aldermans successfully delivered 1,800 precision-manufactured units within a tight two-week deadline, ensuring that Plessey could meet its installation schedule for the Belgian greenhouse expansion project. To manage the high-volume production efficiently, Aldermans implemented a phased delivery approach, supplying components in batches to maintain a steady workflow without delays.

The Hyperion™ LED lighting system is now actively used in large-scale horticultural operations, playing a crucial role in expanding the total cultivation area to 49,000m². This demonstrates how advanced LED technology can enhance sustainable food production on a commercial scale. By providing a high-quality, precisely engineered metal casing, Aldermans played a crucial role in bringing Plessey’s innovative lighting solution to market on time.

This project further strengthened the long-term partnership between Plessey and Aldermans, highlighting Aldermans’ ability to deliver precision-engineered components at scale, under tight deadlines, and to the highest industry standards.

Client testimonial

‘Having previously visited Aldermans’ impressive factory, we had faith in their capabilities to create this part for us. Working with a local supplier was beneficial for us both in terms of the cost and the swift supply. We’re very pleased with Aldermans’ approach and the help they have given us on this project.’

-Mike Snaith, Operations Director Plessey Semiconductors Ltd

let's collaborate on your next big idea

Ready to bring your vision to life?

Whether you’re inspired by our past creations or have a unique concept in mind, our team is here to make it happen. Contact us today to discuss your project and discover how we can turn your vision into reality.