Vispring – Brass Plated Bed Legs

The requirement

Vispring, a luxury bed manufacturer renowned for its craftsmanship, high-quality materials, and bespoke designs, sought to develop a new brass-plated bed leg that could seamlessly cross both the corner and centre of its beds. With a prestigious clientele that includes high-profile sports stars, celebrities, first-class ocean liner cabins, and luxury hotels worldwide, Vispring needed a durable yet elegant solution that matched its exacting standards.

Having partnered with Aldermans for eight years, Vispring was confident that the Plymouth-based manufacturer could transform its vision into a workable, high-quality product. The concept was based on an existing predominantly wooden furniture leg, and Vispring was keen to replicate its antique brass finish while refining the shape into a sturdy, aesthetically refined steel component.

The solution

By collaborating with Aldermans from the earliest stages of development, Vispring combined its creative vision with Aldermans’ technical expertise to move from concept to prototype to full production. This partnership allowed for design enhancements to ensure the final product met Vispring’s aspirations without compromising on quality or lead times.

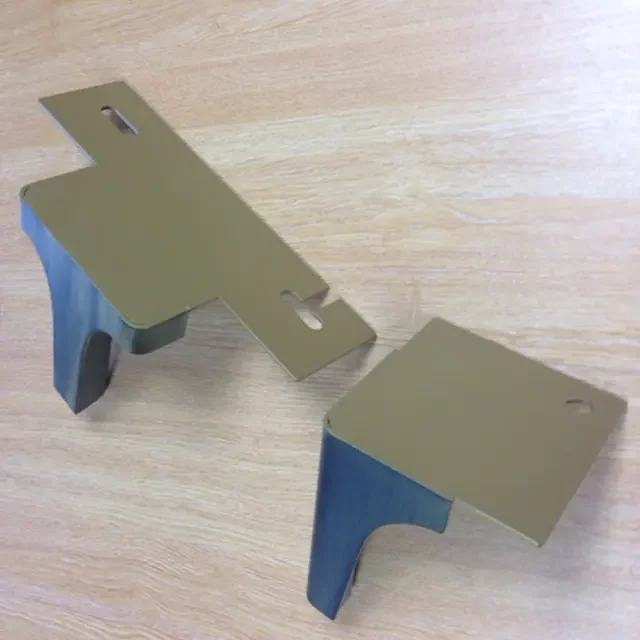

Originally, Vispring planned for a timber and steel leg, but Aldermans recommended an all-steel design to enhance strength and durability. The biggest challenge was achieving the perfect antique brass finish. Aldermans experimented with multiple powder coating applications, chemical treatments, and graining processes to match the original wooden leg’s aesthetic. Through persistence and industry expertise, Aldermans sourced a specialist brass plater to provide the ideal finish.

Manufacturing the bed leg required a range of advanced processes, including laser cutting using an Amada C1 laser punch combination machine, precision metal folding, expert welding, and finally, the plating process to achieve the perfect brass finish.

The outcome

As Vispring’s beds are handmade to order, production timescales can be demanding. Aldermans implemented a KANBAN call-off stock system, ensuring that the brass bed legs are supplied exactly when needed and delivered directly to the shop floor production line.

Vispring’s close collaboration with Aldermans extended beyond manufacturing; being a local supplier allowed Vispring to visit Aldermans’ factory, meet the skilled team, and observe the state-of-the-art CNC machinery and industry-recognised processes in action. This hands-on approach reinforced Vispring’s commitment to craftsmanship, quality, and premium materials—values shared by Aldermans.

Aldermans has built a strong reputation for delivering bespoke, precision-engineered components that combine style, durability, and practicality. By bringing this expertise to Vispring’s brass-plated bed legs, Aldermans has helped the brand maintain its commitment to luxury, quality, and traditional craftsmanship, ensuring every element of its beds meets the highest standards.

Client testimonial

‘Aldermans instinctively knew what we were trying to create and went the extra mile to add the perfect finishing touch.’

-Chris Harrison, Operations Director, Vispring

let's collaborate on your next big idea

Ready to bring your vision to life?

Whether you’re inspired by our past creations or have a unique concept in mind, our team is here to make it happen. Contact us today to discuss your project and discover how we can turn your vision into reality.