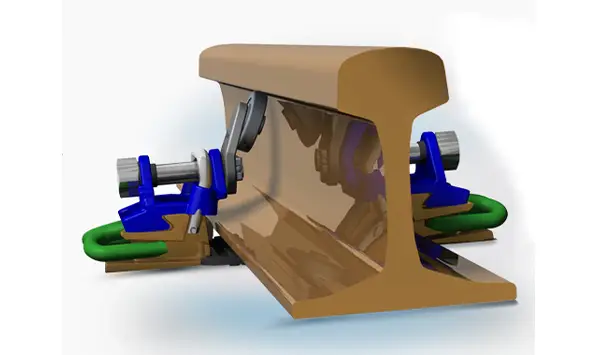

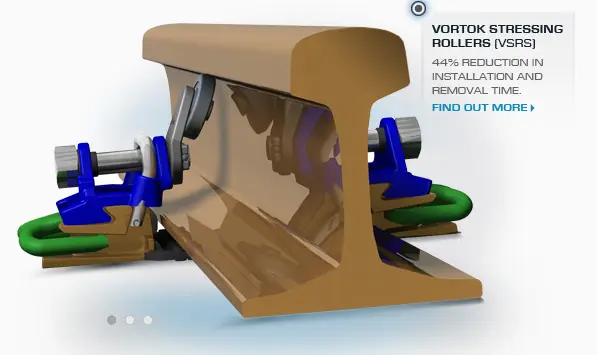

Vortok- Stressing Roller

The requirement

Railway tracks, being made of metal, expand and contract with temperature changes. Without proper stress management, they risk buckling on hot days, leading to serious safety hazards. Traditionally, the stressing process—lifting and realigning sections of track—was time-consuming and labour-intensive, requiring three separate tools: a jack, under roller, and side roller. This method was not only inefficient but also posed a safety risk to maintenance staff, who were vulnerable to crushed fingers.

Vortok International, a Plymouth-based rail industry supplier, sought to revolutionise this process. Their innovative VSR Stressing Roller replaced the three tools with a single, streamlined device, dramatically improving efficiency and safety. The product significantly reduced rail installation and removal time by 44%, halved the manpower required, and minimised the risk of workplace injuries.

To meet growing demand and support international expansion, Vortok required a trusted manufacturing partner capable of high-volume production with tight quality tolerances. In 2006, they approached Aldermans to produce key components for this groundbreaking product.

The solution

Vortok had already designed the required components, but Aldermans was tasked with developing the tooling and manufacturing the parts to precise specifications. A press tool was created to accurately roll the shape of the staple bar. Additional parts, including three separate turned pins, a disc, and a lasered plate, were formed and threaded from EN8 mild steel. To ensure durability and corrosion resistance, all components were zinc and clear plated before final assembly.

Aldermans’ local presence, strong manufacturing capabilities, and ability to combine toolroom expertise with volume production were key factors in winning the contract. After a visit to Aldermans’ Newnham Industrial Estate factory, Vortok’s Procurement Manager, Ron Goldsmith, placed an initial order for 2,000 components. The partnership has since led to many years of repeat business, with Aldermans consistently delivering high-quality components for the VSR Stressing Roller.

The outcome

The VSR Stressing Roller has gained international recognition, winning industry accolades, including the Queen’s Award for Innovation in 2010. The product is now exported worldwide, from Canada to Saudi Arabia to Australia, and has been instrumental in Vortok’s continued growth and success over the last four years.

Aldermans is proud to have played a role in this award-winning innovation, providing precision-engineered components that have helped make railway maintenance safer, faster, and more cost-effective. The long-standing partnership with Vortok is a testament to Aldermans’ ability to deliver high-quality, high-volume metal components that contribute to industry-leading products.

Next time you travel by train, you may well have Vortok—and Aldermans—to thank.

Client testimonial

‘Aldermans has been a key supplier during a rapid period of growth for Vortok, responding to significant increases in demand at very short notice, with great success. We are also grateful for the level of engineering support we receive as part of the service. This collaboration has enabled both companies to reduce product cost and boost competitiveness.’

-Richard Robertson, MD, Vortok International

let's collaborate on your next big idea

Ready to bring your vision to life?

Whether you’re inspired by our past creations or have a unique concept in mind, our team is here to make it happen. Contact us today to discuss your project and discover how we can turn your vision into reality.