Aldermans is proud to announce that four staff members have completed Six Sigma Yellow Belt training.

Ian Barrowdale, Zac Butcher, Scott Gray and Tom Wilson attended the two-day course as part of Aldermans’ continued commitment to improving its manufacturing processes and investing in its valued staff.

Aldermans is proud to announce that four staff members have completed Six Sigma Yellow Belt training.

Ian Barrowdale, Zac Butcher, Scott Gray and Tom Wilson attended the two-day course as part of Aldermans’ continued commitment to improving its manufacturing processes and investing in its valued staff.

Six Sigma is a technique used by businesses to improve product quality by identifying and removing the causes of potential defects. Since being developed by Motorola in the USA in 1986, Six Sigma has gained a global reputation for improving business reliability, consistency and quality.

The course, which was run in collaboration with Plymouth concrete floor firm Permaban, was led by specialist Six Sigma trainer Paul Allen from APL.

As part of the training, Aldermans employees learnt all about Six Sigma techniques and metrics before taking part in a practical exercise where they experimented with a catapult.

Aldermans supervisor Ian Barrowdale explains: “The aim was to get a consistent result each time we fired a model catapult. At first, the results varied quite a lot, but on the second round, after implementing what we had learnt, the catapult started hitting the target almost every time. This was because we had analysed every variable and tried to standardise every shot we made, which made the process a lot more efficient.”

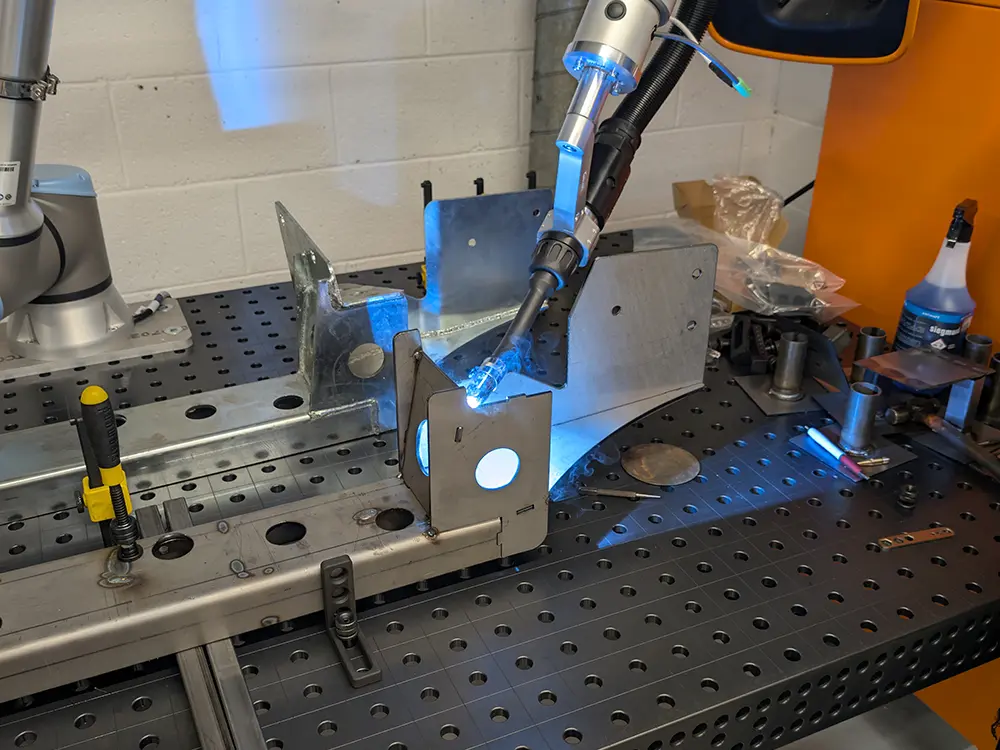

Now the Yellow Belt trained staff are keen to put their learning into practice at Aldermans. Fabricator operator Tom Wilson says: “I found it very interesting and can see it being implemented in the near future in the fabrication department.”