GM Coachwork helps wheelchair users rediscover the joy of the open road by converting regular cars and vans into wheelchair accessible and drive-from-wheelchair vehicles. We have helped GM turn its ideas into bespoke products which make a real difference to quality of life.

GM Coachwork helps wheelchair users rediscover the joy of the open road by converting regular cars and vans into wheelchair accessible and drive-from-wheelchair vehicles. We have helped GM turn its ideas into bespoke products which make a real difference to quality of life.

Being independent isn’t always easy for wheelchair users. It can be a challenge to get in and out of vehicles or even to drive. But having the freedom to travel around can vastly improve quality of life.

Turning a car, van or bus into wheelchair friendly transport is a specialist job: vehicle conversions can involve moving and replacing the fuel tank to enable the floor to be lowered, installing fittings to secure wheelchairs or mobility scooters, as well as adding handrails and ramps.

With automotive design constantly evolving and safety always a priority, GM Coachwork needed a reliable supplier to quickly turn its ideas and models into workable prototypes and products.

Ideas into reality

Aldermans began working with GM Coachwork in 2014 when we were asked to make a new, lightweight fuel tank for its Citroën Berlingo conversions.

GM Coachwork was impressed by our ability to envision and further develop its SolidWorks models into workable prototypes and products.

Now, we manufacture a range of products used across the GM Coachwork portfolio, from handrails made from embossed tube, which are made on a call-off basis, to the Scoot N Stop system, which locks a mobility scooter securely into place. And we’ve just started to make a luggage rack for a new Hitachi van.

Quality assurance

Testing and quality assurance is of the utmost importance. When we developed the aluminium fuel tanks for the Citroën Berlingo we bought a large plastic vessel and rigged up a test so we could check for leaks and make any necessary adjustments before sending for pressure testing. This reduced the risk of test fails and the cost of retesting. All items have to pass through our quality assurance department for consistency once prototypes are approved.

Adaptable

For a business that converts vehicles, adaptability is very important. GM Coachwork appreciates how quickly we can respond to change, particularly as products improve. For example, we usually make minor amendments or improvements to each batch of the Scoot N Stop. It also helps that we are able to manufacture a wide range of products in varying quantities.

One stop shop

We provide GM Coachwork with a complete, local, one-stop manufacturing solution, which means it’s easy to keep in touch – essential when working in such a fast changing environment.

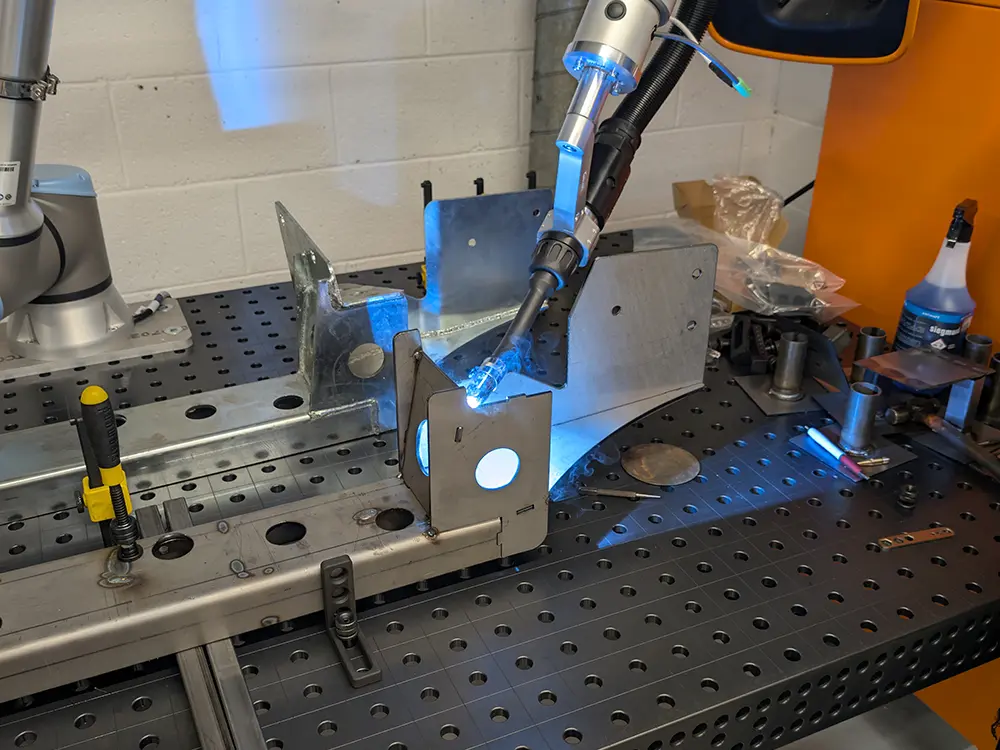

Most GM Coachwork products take advantage of a range of our facilities including the machine shop, lathe, mills, laser, press brake, aluminium welding, and our new powder coating facility.

“Aldermans has worked with the GM Coachworks Research and Development team to manufacture new and existing products from parts or templates and 3D solid models. By working with the stores team, they have secured new projects and ongoing repeat business to allow GM Coachworks to order on a Just In Time basis.”

Matt Smith, Marketing Manager, GM Coachwork UK